Course Details

Home / Public Courses / Course Details

ONLINE: Wireline and LWD Log Quality Control and its Impact on Interpretation (PPH925)

Description

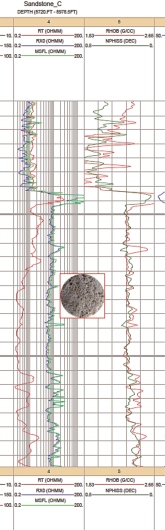

The certification of acquired data is a very critical aspect of wireline and LWD logging and is performed through the observation of key quality indicators. The main objective of this course is to make you aware of these quality indicators as well as the different techniques to solve commonly found issues at the wellsite.

The course will explore the tools response explained from their physical principles as well as their relationship with the rock and fluid properties, most common open hole logging technologies will be covered explaining their main applications and limitations. Basic petrophysical interpretation will be discussed with several examples and exercises in order to complement your knowledge to be able to perform a proper log QA/QC analysis.

This training course will feature:

Course Structure: 4 days, 4 hours per day, with ample time for delegates to break for refreshments.

Course Level: Foundation / Skill

Duration: 4 days

Instructor: Angel Meso

The course will explore the tools response explained from their physical principles as well as their relationship with the rock and fluid properties, most common open hole logging technologies will be covered explaining their main applications and limitations. Basic petrophysical interpretation will be discussed with several examples and exercises in order to complement your knowledge to be able to perform a proper log QA/QC analysis.

This training course will feature:

- Explanation of petrophysical concepts and techniques

- Discussions on tools physical principles, applications and QA/QC

- Tool limitations on different borehole environments

- Multiple log quality control exercises

Course Structure: 4 days, 4 hours per day, with ample time for delegates to break for refreshments.

Course Level: Foundation / Skill

Duration: 4 days

Instructor: Angel Meso

Designed for you, if you are...

- An engineer in exploration and production departments

- A geologist, geophysicist or petrophysicist

- A petroleum, reservoir or drilling engineer

- In general, any other oil & gas industry professional involved in logging data QA/QC and validation

How we build your confidence

- This training course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented.

- The sessions will be given in real time through live webinars (instructor-led training); some exercises will be executed during the sessions, others will be done as homework.

- The daily sessions will be highly interactive and participative. This involves regular discussions of applications as well as hands-on exercises that will be solved manually and/or using Microsoft Excel.

The benefits from attending

By the end of the course you will feel confident in your understanding of:- Physical principles of main wireline and LWD logging tools

- Applying quality control techniques to validate logging data

- Main applications and limitations of the different tool readings

- How to perform a complete log quality control in a set of logs

- How to perform a basic log interpretation

Topics

Basic Logging Concepts and Principles of Metrology- Basic well logging concepts

- Auxiliary measurements, QA/QC and common issues

- Principles of metrology, the real environment

- Log quality control basic principles

- Basic measurements: Gamma ray and spontaneous potential

- QA/QC indicators and examples

- Resistivity theory, principles and applications of laterologs

- Microresistivity devices, principles and applications

Conductivity and Nuclear Logging Tools

- Conductivity tools, uses and limitations

- LWD Resistivity Determination Tools

- Log quality control and common issues

- RT and invasion profile determination

- Formation density tools, calibrations, applications and QA/QC

- Neutron tools principles, calibrations, applications and QA/QC

- LWD Porosity Determination Tools

- Nuclear tools limitations and environmental corrections

Acoustic and Geological Logging Tools

- Basic sonic tools, borehole compensation

- Dipole sonic tools, applications

- Mechanical properties determination and uses

- Sonic limitations, QA/QC and common issues in the borehole

- LWD Acoustic tools

- Cement evaluation logs: CBL-VDL. interpretation and QA/QC

- Ultrasonic cement evaluation tools

- Dipmeter interpretation principles

- Geological image (resistivity and ultrasonic) logging tools

- Principles, interpretation and log quality control indicators

- Structural and stratigraphic interpretation principles

- Facies analysis for reservoir characterisation with image logs

Advanced Logging Tools and Formation Testers

- Nuclear magnetic resonance, applications, limitations and QA/QC

- Relaxation mechanisms and their association with fluid and rock properties

- Porosity, irreducible water saturation and permeability determination

- Advanced fluid determination methods: 3D map T1-T2-difussion

- Dielectric tools principles and applications

- Saturation determination parameters, m, n and CEC

- Geochemical logging tools, uses, limitations and QA/QC

- Reservoir pressure determination tools

- Pre-test interpretation, common issues and QA/QC

- Pressure gradient interpretation and examples

- Fluid sampling, optical and composition fluid analysers

- Advanced probes for special well and reservoir conditions

- Permeability determination

Well Seismic and Basic Petrophysics

- Checkshot, VSP, offset and multi-offset VSP, walkaway

- Different source types, air-guns and vibroseis trucks

- Physical principles, interpretation and log quality control indicators

- Formation evaluation principles

- Rw determination methods

- Crossplots utilisation, Hingle and Pickett plots

- Graphical interpretation techniques for porosity and lithology

- Saturation determination equations and techniques

- Complete formation evaluation for simple lithology

Related Courses

Customer Feedback

"Complex materials are presented very clearly." - Technical Advisor at Gazprom"Instructor's explanations were very clear and patient." - Petrophysicist at RDG

"Good high tempo, many subjects." - Geologist at Petrogas

"Lots of new information about log quality control. Great experience, thanks." - Specialist at NIS

© All rights reserved

HOT Engineering GmbH Tel: +43 3842 43 0 53-0 Fax +43 3842 43 0 53-1 hot@hoteng.com